FOREST LINE-CRANES

FOREST LINE-TRUCKS

BENEFITS

Stores up to 2000 weights.

Recorded by: date and time, the batch in which you are working, surface of the batch, type of grain,% moisture of the harvested grain. (truck license, identified bag, identified silo, consignment note or field name)

Returns individual and total information for each record.

Alphanumeric keyboard for entering the information previously detailed.

Calculate the yield per hectare.

The data can be read from the indicator.

Print a ticket from the indicator or download them to your PC to store and manage them through an Rs 232 or USB port.

Optional printer

Mobile phone application

CLAW SCALE

KEY FEATURES

COBA-30000 axial census cell.

Multi-board force measurement system.

Zero and temperature compensation.

Mechanical protection against accidental blows.

Environmental Protection.

Cell built in tempered and tempered SAE 4140 steel.

Verification of mechanical resistance using the finite element method.

TARGET

The COBA-3000 load cell is intended to measure, with superior precision, the load applied to the claw of the forestry crane and therefore the weight of the load that the crane is lifting.

DESIGN AND ASSEMBLY

It seeks to measure in the pivot area that supports the claw. For this, a load cell with an adapted design is used that replaces the pivot part, thus achieving precision measurement and maintaining mechanical resistance at a low cost and with an installation saddle.

ADVANTAGES REGARDING PRESSURE SENSOR BASED SYSTEMS

Simple design: fewer components. Direct measurement of magnitude. Higher precision: 0.03% at full scale.

Reproducibility: due to its physical principle of operation, it has a stable census, also counting with compensation for zero temperature errors and gain. It derives from the indication with extremely low time, before taking an instant indication of weight.

ADVANTAGES WITH RESPECT TO OTHER FORCE SENSORS

Column-type force sensors are often used in tensile applications, based on the measurement of axial and diametrical deformation of the body, which is converted into a proportional electrical signal. This type of sensor deforms in a different way in the axial and diametrical axis, so that non-linearity occurs when the applied force varies. This phenomenon is compensated by means of algorithms, but it is not always the best solution, here the new system called Multi-board enters the scene, where the axial and diametral deformation are coupled to the deformation of a ring, making them equal in magnitude.AT - 455

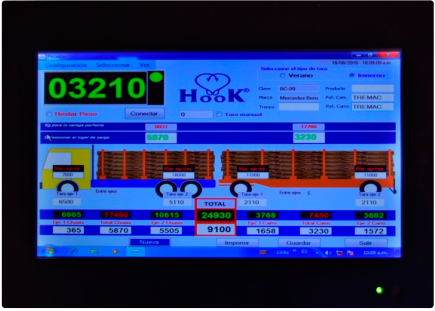

MONITOR AT - 1000

INTELLIGENT WEIGHING SYSTEM

It enables trucks to be loaded by identifying the kilos transported on each axle of the truck using the claw scale.

Supports multiple body configurations.

Maximum dispersion of 0.5% in total load and 1% in axle weight.

The truck's dimensions and tare are raised and loaded into the system so that the crane operator can then choose the truck at the time of loading.